Congratulations on this step to better health.

This eMail is needed to tell you things that are VITAL to your ownership, startup, use and enjoyment of the AquaCure AC50 PLEASE read ALL this eMail!

First VITAL: Your Eagle-Research User Account…

When you purchased your AquaCure, if you didn’t already have one, the website automatically created an account for you (usually based on the eMail you used to order) and sent you the account details (including the password). This is NEEDED to access your online Resources.

If you did not receive the password eMail, check your junk or spam folders and if it’s there, drag it into your inbox, to whitelist us. The internet is NOT KIND to our eMails…

If you cannot find the eMail, you can still get into your user-account by using the ‘lost password’ procedure.

https://eagle-research.com/my-account/edit-account/

Then you can change the password to whoever you want and Very Important… Press UPDATE at the bottom of the page to tell the website to remember your changes.

If you DON’T receive the ‘lost password reset’ eMail (sent to the eMail address you used to purchase the AquaCure), then your eMail SERVER (Hotmail, gmail, yahoo, etc.) is deleting the automatic eMails from our website before they get to you.

Nothing I can do about that.

But YOU should be able to talk to whomever is serving your eMails and tell them to whitelist

website_emails@mg.eagle-research.com

NOTE: Since you purchased the AquaCure from us directly, your AquaCure IS REGISTERED and your Satisfaction Guarantee and Lifetime Warranty are started.

There are things that we cannot say online (AquaCure Sales Page) or organizations like customs or the FDA will not deliver the AquaCure to you and/or shut us down.

The issue is that the AquaCure is not registered as a ‘Medical Device’ AND we are not Doctors (as certified by Big Pharma indoctrination) thus we cannot make any claims or even imply that it can be used for Human ailments.

https://eagle-research.com/legal-medical-disclaimer/

We ARE working to get certification (we are paying for appropriate scientific studies), but the process is time consuming (will take years) and expensive (might take millions of dollars) even if they do approve it in the end. And they might not…

Because products that do what the AquaCure can do (virtually eliminate most of the drugs big Pharma sells) are treated with extreme prejudice… Where products that harm people are often immediately approved, at Warp Speed and without appropriate safety testing… Such is the upside down world we now live in…

So HERE, in a personal eMail to YOU, we will tell you what you need to know and we invite you to ask questions if needed. But do please read review the links below first and then be specific with your questions, our people are working hard to help everyone.

First to know, the AquaCure AC50 Operation Manual is NOT INCLUDED in the AquaCure box (because it contains details for human use of the AquaCure). You can download the current Operation Manual Here

https://eagle-research.com/wp-content/uploads/2019/08/AC50-Operation-Manual190414.pdf

What is included in the AquaCure box is a ’throwaway’ instructions pamphlet (from the original VING chassis) on how to setup to fuel a MICRO-TORCH…

Which the AquaCure CAN do and will be needed to apply protocols 5 and 6 (DDW and New Water).

Use as a micro-torch is 100% LEGAL and what you would say if anyone calls you and asks what your ‘end use’ is…

The micro-torch is not included ‘just for show’… In addition to the great fun you can have using the micro-flame, it has EXTREME VALUE for HEALTH. And we will tell you about protocols 5 and 6 when we get current projects taken care of.

Again, subscribe to our eNews for notification when we are ready.

Because the AquaCure AC50 developed (upgraded) faster than the instructions, here is the Operation Manual UPDATE, which has information that supersedes the Manual

https://eagle-research.com/wp-content/uploads/2021/11/AquaCure-Operation-Manual-Update-Notes.pdf

Our intention is that you print the Operation Manual and Update for yourself.

If you wish to purchase a paper copy of these Operation instructions, you can buy them from:

https://eagle-research.com/product/aquacure-operation-manual/

And they will be shipped separately from the AquaCure Box.

We ARE making an amazing, new and professionally done, AquaCure AC50 Assembly and Operation Manual, that will replace the above once done.

Subscribe to our eNews to be informed when it is ready.

NEXT (NOT included in the Box) is the Nasal Cannulas. Those are a dead giveaway that the AquaCure in the box is intended to be used for Humans. ‘They’ occasionally open the boxes enroute, and examine the contents, so we need to be careful what is IN the box. We cannot have cannulas in the box…

So, there are MANY places you can purchase nasal cannulas online and get them very fast.

For example:

https://www.amazon.com/s?k=nasal+cannula+adult+soft+touch+7%27+tubing&crid=OLNCYOEO4W3G&sprefix=nassal+cann%2Caps%2C90&ref=nb_sb_ss_ts-doa-p_10_11

If you wish to purchase cannulas from us, we sell them here:

https://eagle-research.com/product/nasal-cannulas/

and they are SHIPPED SEPARATELY from the AquaCure Box

Click here to see an impromptu AquaCure AC50 Setup and Operation Video.

https://youtu.be/723gzax3z7Y

We ARE making better (professionally done) videos and those will be available to you once done.

Subscribe to our eNews to be informed when they are ready.

THIRD, Lye IS usually included in the box, but sometimes customs removes it (it’s a white powder) so we cannot guarantee that it will arrive.

Again, lye is easy to buy online, for example:

https://www.amazon.com/Lye/s?k=Lye

AquaCure New Timer Switch

https://youtu.be/P0J4GxuddxM

Apply Teflon Tape on AquaCure Fill Stem

https://youtu.be/sFXJaOSwwZs

Properly Install the Tower Cap

https://youtu.be/Pr98DMe94No

Make sure your Tower Cap base Union is sealed properly (it may take up to 30 wraps of Teflon Tape and that (in the future) you remove the Tower Cap using the Union ring (no need to remove the Union base), so you do not need to keep re-applying the Teflon Tape.

DO NOT ’torque’ (twist) on the Tower Cap itself to seal the Union base fitting; doing so will ‘lock up’ the big Union ring, requiring wrenches to loosen it.

ALWAYS install the Union base FIRST (look for the white box), THEN put the Tower Cap on the base.

A band wrench is now included to help you tighten the Union base onto the Fill stem.

AquaCure Rinsing Technique

https://youtu.be/oac55WgfIvs

When Rinsing:

To dissolve soap formations and lye crystals you need water in the 120° F to 140°F range. The water must be hot; warm water does little.

Remember to trade out the hot water within a minute or so (at first) because it will cool quickly as it heats up the components.

You Fill the AquaCure to FULL with HOT water (6 to 7 cups). Then alternately and SLOWLY lift the front and back of the machine up to 60 degrees to ‘wash’ the HOT water up and down in the Sight Tube.

You need to change out the HOT water frequently because it cools off quickly and warm water does little to dissolve soap.

NOTE: If the HOT water doesn’t ‘’reach’ the tight tube, doesn’t wash’ up and down in the sight tube, it CANNOT clean the sight tube; if you are not getting the water washing up and down in the sight tube, it’s likely due to a plug or restriction that needs to be fixed ‘manually’; ask for instructions.

Note: I occasionally get an ‘air bubble’ in the tube (so it will seem that the sight tube and/or ball is not ‘registering’ the actual fluid level correctly).

Generally air bubbles will eventually clear on their own, but you can ‘hurry’ the process by filling the AquaCure with solution. Then alternately and VERY SLOWLY lift the front and back of the machine up to 60 degrees to ‘wash’ the solution up and down in the Sight Tube, washing out the air bubble(s) and then the ball should float properly.

H2 Hubb AquaCure AC50, Unboxing, Setup and Test videos:

Unboxing https://www.youtube.com/watch?v=i5CAuVYu_a4&t=368s

Setup https://www.youtube.com/watch?v=PAmDyKdai4Y

Test gas production https://www.youtube.com/watch?v=w1GOztHEOgk

Optionally: Setup your AquaCureAC50 torch attachment:

https://youtu.be/v2ufQWJ0l0Q

See Brown’s Gas testimonials / studies / etc. here:

http://eagle-research.life

AquaCure Brochure

https://eagle-research.com/wp-content/uploads/2020/02/AC-Brochure-small-v4generic.pdf

Brown’s Gas for Health (legacy page)

https://eagle-research.com/browns-gas-for-health

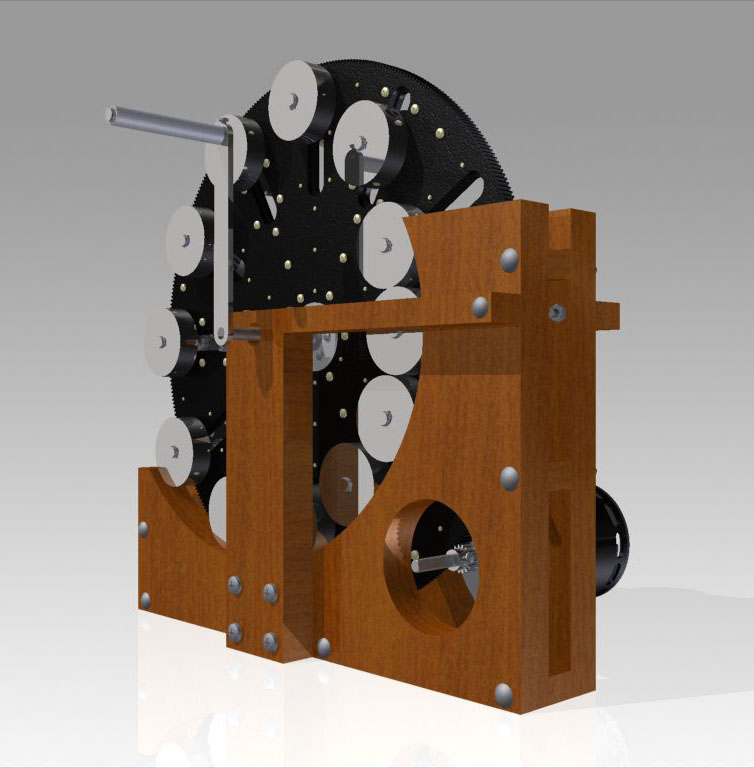

What is Brown’s Gas?

https://eagle-research.com/q-what-is-browns-gas-bg/

Why would you want Brown’s Gas in your life?

https://eagle-research.com/why-does-browns-gas-supplementation-help-health/

Why is Brown’s Gas better than pure hydrogen?

https://www.youtube.com/watch?v=amruwdyj3j0

I cannot legally tell you how to use your AquaCure for health (that’d be ‘prescribing’) but I can tell you how I use it

https://eagle-research.com/how-i-use-browns-gas-for-health-enhancement/

Plants Don’t Lie

https://eagle-research.com/plants-dont-lie/

Purchase your AquaCure model AC50 here:

https://eagle-research.com/product/ac50/

May the blessings be

George Wiseman

George Wiseman