Access Protected

You must be logged in and have purchased one of the following products to view this content

You can login here if you are a returning customer

You must be logged in and have purchased one of the following products to view this content

You can login here if you are a returning customer

You must be logged in and have purchased one of the following products to view this content

You can login here if you are a returning customer

FEA eBook Resources

Bird, Christopher and Nichelson, Oliver; Great Scientist, Forgotten Genius Nikola Tesla. Published in New Age, pages 36-44, 66, 72-74.

Crump, Lloyd R.; Patent number 2,813,242, patented Nov. 12, 1957, “Powering Electrical Devices with Energy Extracted from the Atmosphere”.

Edmund Scientific Company,

101 East Gloucester Pike, Barrington, NJ, 08007-1380,

Phone (609)547-8880

Jefimenko, Oleg D.; 1973, Electrostatic motors.

Published by Electret Scientific Company,

PO Box 4132, Star City, WV, 26505, USA.

International Tesla Society Inc.,

PO Box 5636, Colorado Springs, Colorado, 80931.

Moray, Henry T.; 1978, The Sea of Energy in Which the Earth Floats. Published by Cosray Research Institute, 2505 South 4th East,

Salt Lake City, UT, 84115.

Otis, Douglas; 1993, “Material presented demonstrating negative energy cycles of nuclear power plants”. 4805 Tumbleweed Way, Paso Robles, CA, 93446-4216.

Plauson, Hermann; Patented June 9, 1925, US Patent Number 1,540,998, “Conversion of Atmospheric Electrical Energy”.

Tesla, Nikola; 1900, The Problem of Increasing Human Energy, with special reference to the harnessing of the sun’s energy. Originally Published in “The Century Illustrated Monthly Magazine”, June 1900. Re-published by High Energy Enterprises, Inc. PO Box 5636, Security, CO, 80931, USA; with introduction by Jeffery A. Hayes and Steven R. Elswick.

Tesla, Nikola; 1901, Patented Nov. 5, 1901, Patent number 685,957, “An Apparatus for the utilization of Radiant Energy.”

Tesla, Nikola; 1931, “Our Future Motive Power”. Published in “Everyday Science and Mechanics”, December, 1931; pages 26 to 28, 78 to 81 and page 96.

Trinkaus, George; 1988,

Tesla The lost Inventions.

High Voltage Press, 4326 S. E. Woodstock, #489, Portland, OR, 97206, USA.

Xtal Set Society, PO Box 3026,

St. Louis, MO, 63130.

_____________________

Free Energy Accumulator Reader Comments:

i just finished to read your FEA book, i suggest Instead of using an aerial, try to use a Tesla Coil which produces very high currents if the primary winding is placed in the middle of the secondary winding and not at one end which is the usual configuration. Tesla directs the output on to a single metal plate and powers a load between the plate and the earth. Don Smith demonstrates this in a video currently on YouTube.

He uses a C made from two metal plates with a sheet of plastic between them, instead of Tesla’s insulated single plate. The load is powered between the capacitor and earth and with a 28-watt hand-held Tesla Coil he manage to produce what looks like several kilowatts of power in the earth line…

here you can find the videos of don smith , smart guy

pt3 TMT Magnifying Transmitter,

Don Smith, Resona…: http://youtu.be/RdXDl8rKOgM

Don Smith Generator: http://youtu.be/8EMuVrMdeAg

Don Smith Coil http://scribd.com/doc/188158131

Don Smith Device 2006 http://scribd.com/doc/64090673

Don Smith eBook http://scribd.com/doc/128645927

_____________________

You must be logged in and have purchased one of the following products to view this content

You can login here if you are a returning customer

__________________

1. Please have a look at: http://der-am-rad-dreht.de/ and click ‘next’. It’s a type of waterwheel, but driven by pumping air at the bottom floater.

Thank you for the link.

The problem with this type of wheel is that it takes more energy to pump the air into the bottom of the chamber than you get back from the buoyancy power imparted to the wheel.

2. Have you heard of the Kinetic Power Plant from Swiss, from a company called Rosch?

No.

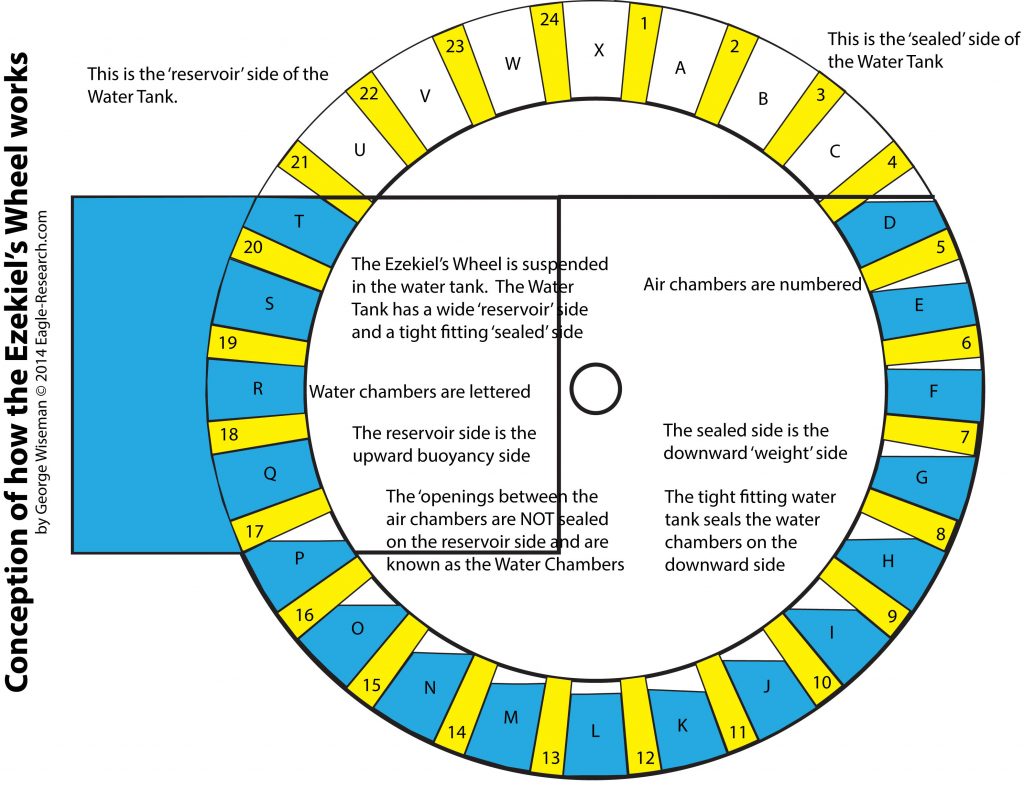

Has similarities to Ezekiels wheel. They are building a 100 kW prototype near the airport of Koln, Germany. I expect to go there beginning of 2015.

I’d love to hear more.

I’ll come back to you with more.

__________________

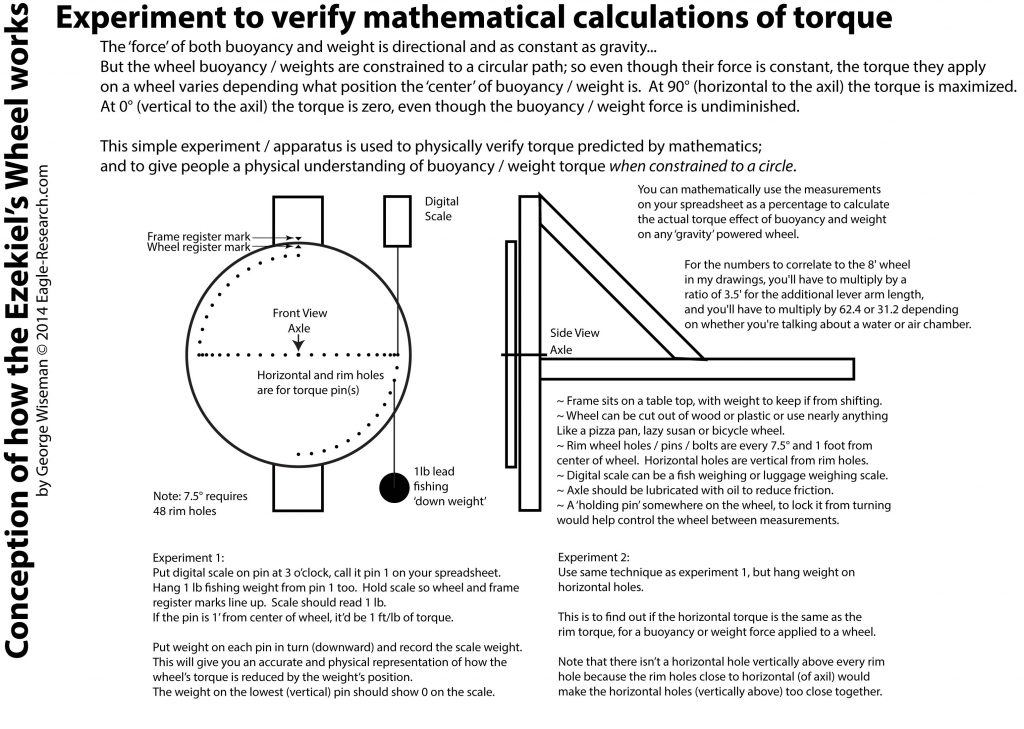

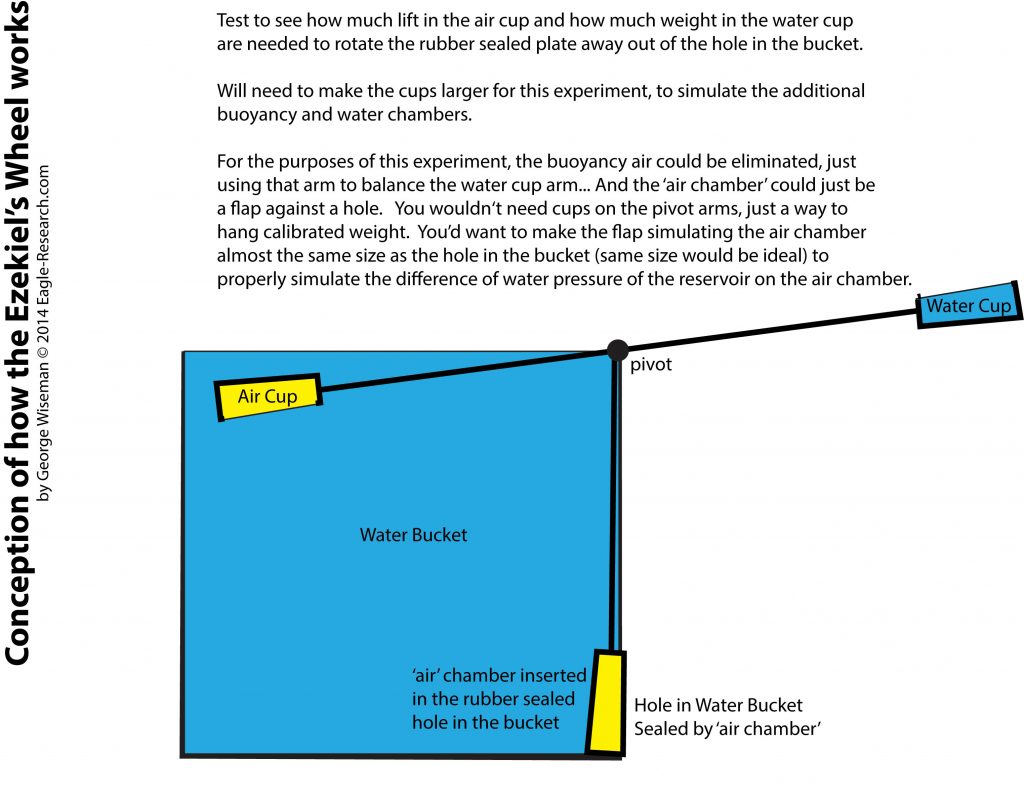

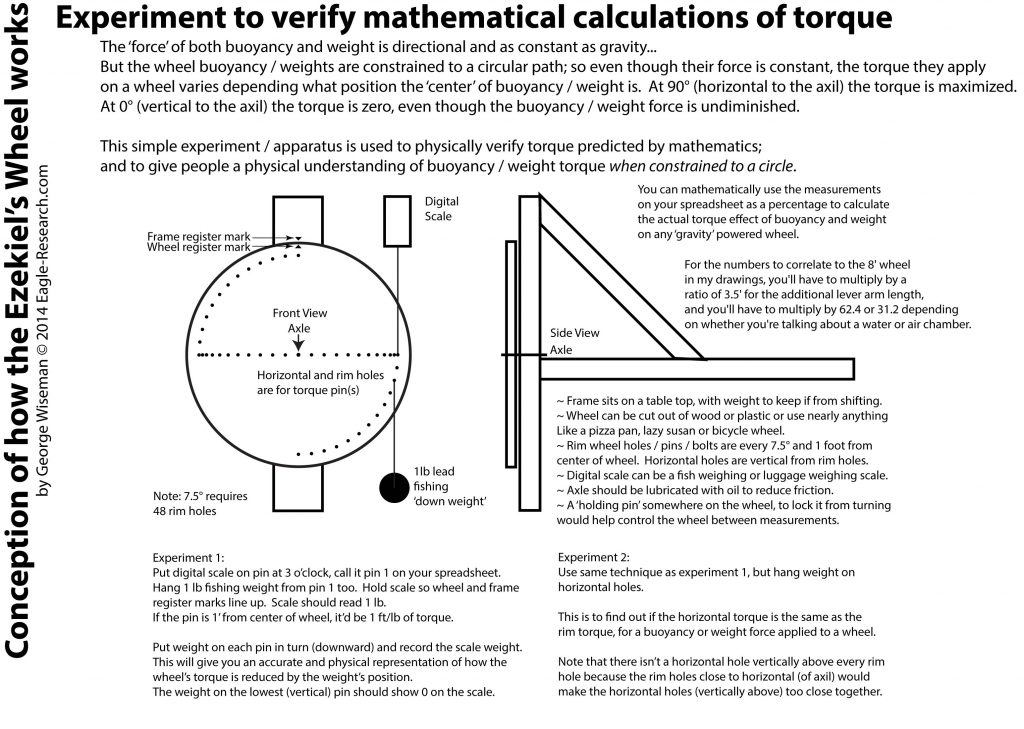

Math is great, but actual physical tests are better if you can simulate the working principles closely enough. There may be (and I suspect there are) things going on that the math isn’t taking into account.

Once you understand (and can physically prove) the working principles, you can do fine tuning to make an efficient machine… Maybe even one that is practical OU.

Here are some thoughts to address what I consider to be the main issues:

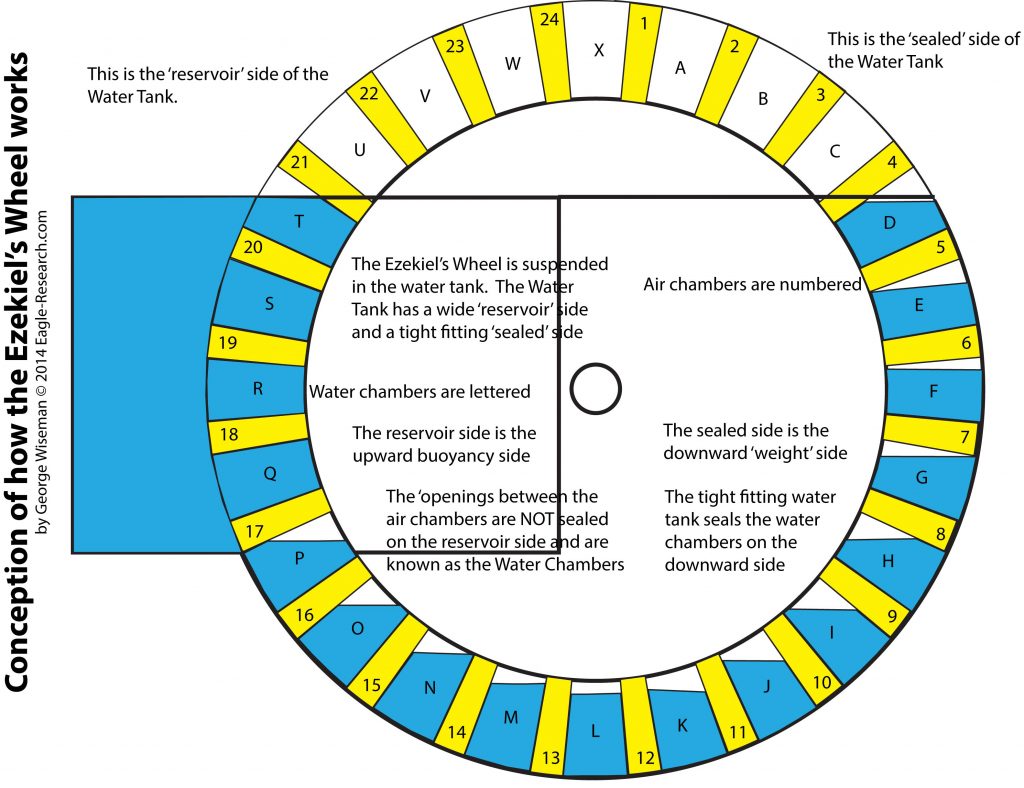

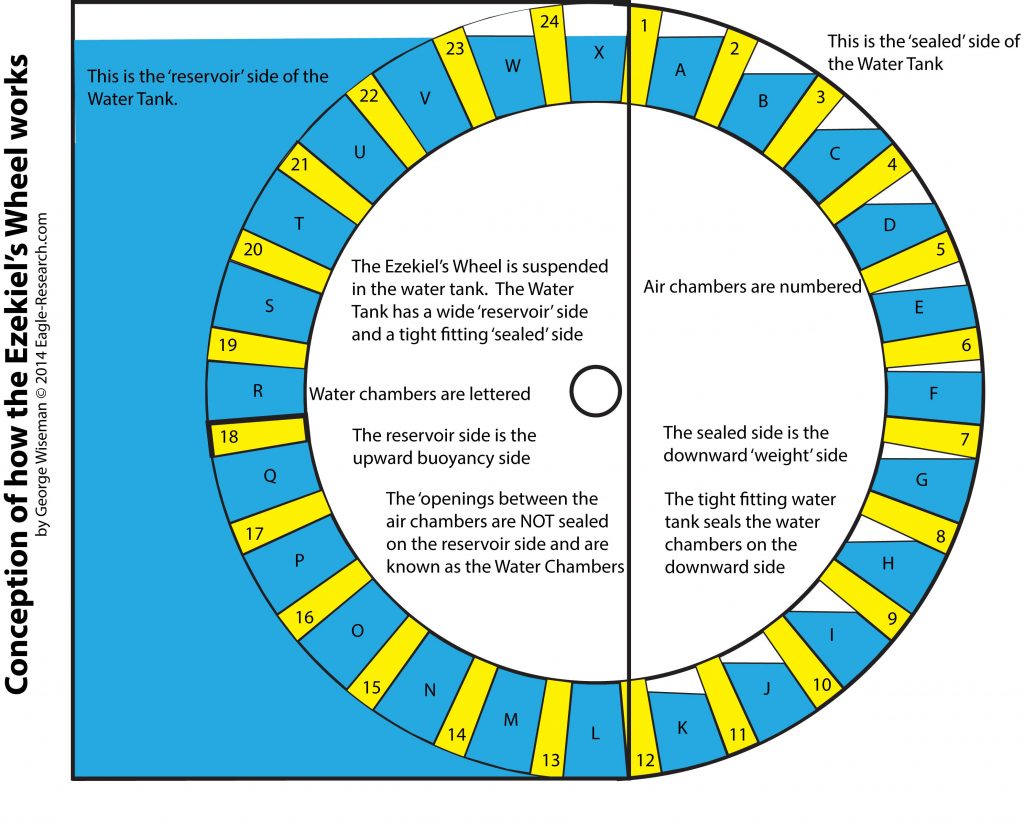

One of the things needed with any technology is setting standards so that people can talk to each other without confusion. Once there are standards, various tests and comments can be compared. BTW, one person called it the EZ wheel; I liked that.

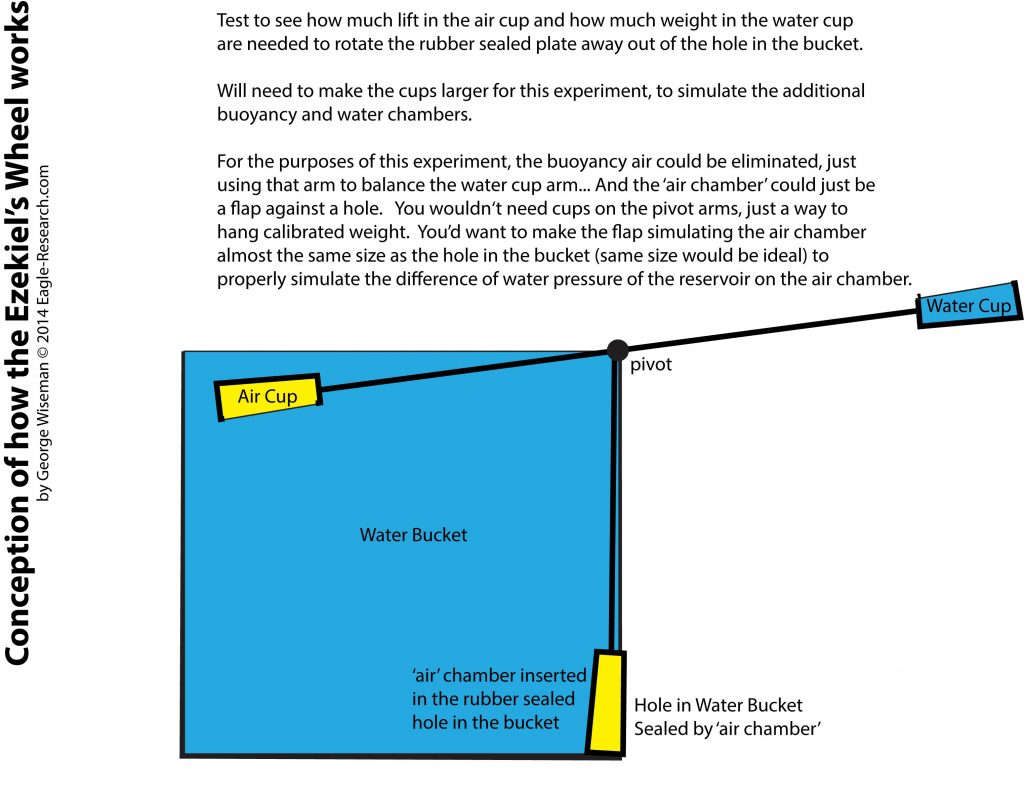

The biggest issue to overcome is the torque needed to force the air chambers into the water reservoir. Here is an experiment that’ll help people understand the ‘water pressure’ issue… And try various things to reduce the pressure or help the wheel move against it.

This is where some innovation is still required. I have some ideas, which I’ll introduce shortly. Anything we can do here will increase the efficiency of the wheel.

Some people (including me) have trouble conceptualizing mathematical equations and sometimes the math is miss-applied or incorrect for the forces involved. Here’s a simple apparatus / experiment that’ll help people ‘get it right’ and perhaps ‘see’ things that will help.

Like I can see that most of the wheel’s torque occurs in about a 60° range, 30° above and below horizontal. Buoyancy and weight have much less effect on the wheel’s power output above or below this ‘torque range’.

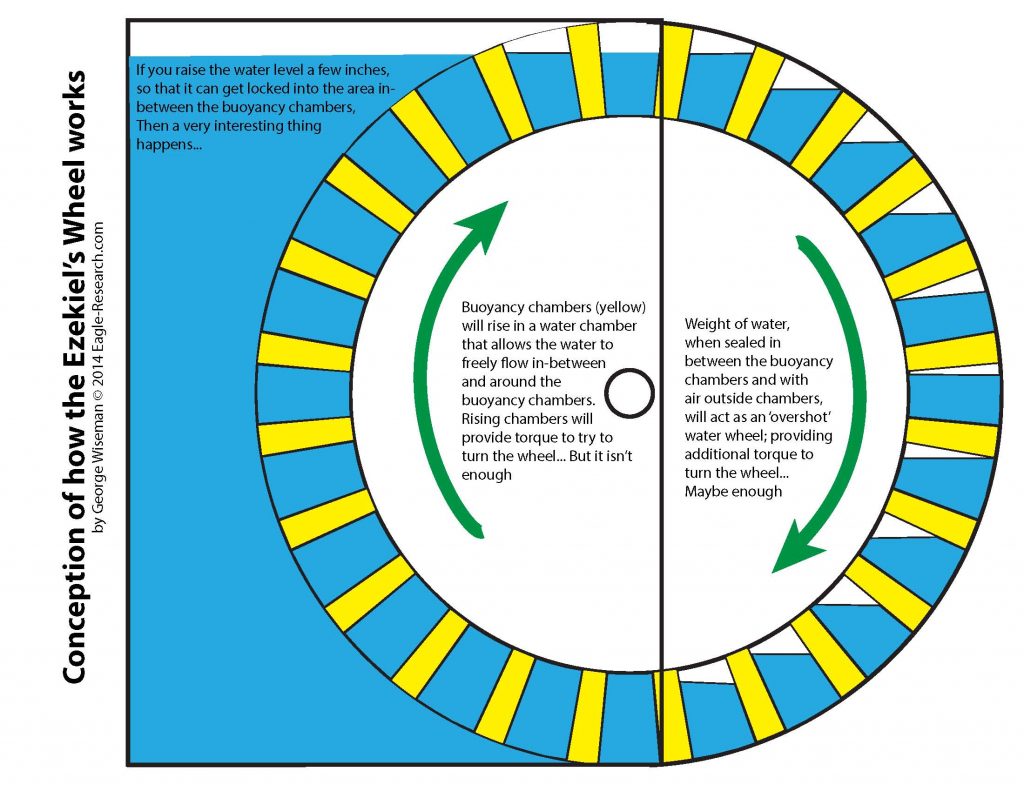

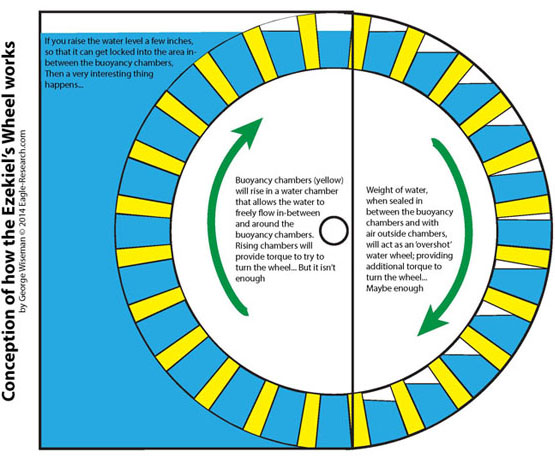

Soooo maybe… if we configure the wheel’s seals (and maybe water reservoir) so that the reservoir’s water pressure can pressurize (be common) up to 30° on the downward side, then the air chambers are entering the reservoir at a higher water level, where there is less water ‘back-pressure’.

Yes, we lose some torque on the downward side but it’s less effective torque anyway and we also lose back-pressure against the wheel.

Also the buoyancy ‘back-torque’ on the downward side will be compensated by the buoyancy on the upward side; so except for friction, I think we end up with a net gain.

It may even be that this effect is already happening naturally in the real wheel, with the 1/16th inch clearances allowing limited water leakage, ‘filling’ and pressurizing the lower chambers on the downward side. The pre-pressurization would allow the air chambers to enter the main reservoir with less back-pressure.

1. As for which side of the axle the water reservoir should be on. I see no great advantage to torque either way, so I like the idea of having the axle out of the reservoir.

2. Yes, you do lose water out of the water chambers as they rise out of the water reservoir, but in my concept of ‘lowering the water level’ I specifically FILL the water chambers with a horizontal tube/pipe/channel that is on the outside of the wheel, at about the ‘D’ level.

Lowering the water level reduces the back-pressure without seriously affecting the Ezekiel’s Wheel torque, because (as you’ll see if you do the torque experiment) any buoyancy / weight beyond 30° above and below the horizontal to the axle quickly reduces to zero.

3. It also occurs to me, that since the most effective torque the wheel generates is in the 30° range above and below the horizontal of the axle, that keeping the water chambers SEALED (away from reservoir pressure) until they reach about ‘P’ on the wheel, may also mitigate the reservoir water pressure since the air chambers would be entering the reservoir at that higher level.

This would be a great modification to the ‘water pressure’ experiment (hole in the side of the bucket plugged with a cork). I’m not sure what would be the best method to represent this aspect/idea… Maybe just lower the water level in the bucket appropriately?

A combination of the two above ideas would allow the water weight to generate torque on the downward side from about ‘D’ to ‘G’, the area between ‘H’ and ‘O’ would be pretty much neutral, buoyancy would take over at about ’17’ and generate torque until about ’20’ and the wheel would be neutral over the top.

‘Reverse’ water pressure would be the water pressure from ‘high level’ (about ‘T’) to the entry at about ’17’. So we’d be having maximum torque with minimum back-pressure.

Here’s a drawing of the concept. In this case the water tank stays sealed to the wheel until the wheel enters the bottom of the reservoir… And there is an exterior horizontal water channel at the top, leading from the reservoir to the sealed side, which I didn’t depict.

Calculating Torque.

Online torque calculator

http://frictionhinge.com/calc.html

Torque of a water wheel

http://24volt.eu/eng_kalkyl_vridmoment.php

Water Wheel torque formulas

http://ffden-2.phys.uaf.edu/211_fall2010.web.dir/Brooks/water-wheel-physics.html

FAQ: What is Buoyancy?

http://www.newton.dep.anl.gov/askasci/phy05/phy05225.htm

http://www.hp-gramatke.net/pmm_physics/english/page0550.htm

https://www.physicsforums.com/threads/gravity-force-and-buoyancy.5208/

Archimedes Wheel

http://www.nuenergy.org/generator-driven-by-a-buoyancy-engine/

Finding center of gravity and center of buoyancy.

http://www.planetseed.com/mathsolution/floating-and-stability-center-buoyancy

http://www.engineeringtoolbox.com/centre-gravity-buoyancy-d_1286.html

http://spot.pcc.edu/~lkidoguc/Aquatics/AqEx/Water_Buoyancy.htm

‘Regular’ Water Wheels:

http://www.borstengineeringconstruction.com/Overshot_Water_Wheel_Design_Calculator.html

http://www.borstengineeringconstruction.com/Undershot_Water_Wheel_Design_Calculator.html

http://www.waterwheelplace.com/main.html

http://www.permies.com/t/19874/hydro/rpm-water-wheel-wheel-high

I don’t know if any Gravity Wheel has ever worked.

I do hope they did and I hope my CCG Wheel will.

I tend to believe it when I replicate it for myself.

However, seeing history is inspirational for me, so perhaps for you too…

Perpetual motion and Gravity Wheel discussion

Here is a long series of Gravity Powered prime movers. Very interesting reading and I can see how to make some improvements to the designs using the ‘gravity rules’ I outline in the Wiseman’s Wheels eBook.

The Kidd design, demonstrates anti-gravity.

Rumors from Russia, Gravity Wheels powering homes. Here are many more videos detailing this design. I think he’s on the right track! I like this one to show a gravity wheels ‘pendulum effect’.

Abeling Gravity Wheel. Has a ramp similar to the CCG Wheel. Supposedly to be legit.

I like this Gravity Wheel concept really much. The one way bearings are a nice touch. He needs to put a ramp on the top and bottom, to move the weights out and in appropriately.

This Gravity Wheel looks really interesting in that it’ll even self-start but they don’t allow it to rotate 360° and I’m not sure why? I’d add a ‘ramp’ on the bottom to cause the weights to flip inward (like the top ram flips them out) instead of just allowing them to hang on the upward side.

Here is a magnetically assisted Gravity Wheel. I’ve seen this one a few times and would like to see a replication attempted.

Designing a Gravity Engine.

Learning from Darrell VanDuesen failures.

Scott Hall’s Gravity Wheel.

The ‘ANDY’ Gravity Wheel.

A collection of Gravity Power ideas.

Gravity Wheel Patents: (click) (click)

‘Wobble’ Gravity Power (not a wheel).

Rex Research Gravity Wheels

http://www.rexresearch.com/skinner/skinner.htm

http://www.rexresearch.com/infolios/kromrey.pdf

http://www.rexresearch.com/kostoff/kostoff.html

PesWiki Collection:

http://peswiki.com/index.php/Directory:Gravity_Motors

Bessler Wheel Links:

http://www.besslerwheel.com/

Discussion of Bessler Wheel. Bessler Wheel tidbits. Bessler Wheel website.

All things Bessler. Sir Issac Newton’s Bessler Quote. Bessler Witness Statements.

Why Gravity Wheels can work. Another site by John Collins. A blog by John Collins.

On the other hand, Sir Issac Newton considered that a perpetual motion machine could be possible when interacting with gravity.

‘Buzz-Saw’ Wheel Links:

http://peswiki.com/index.php/Directory:BuzzSaw_Gravity_Wheel

http://www.panaceatech.org/BuzzSaw

http://www.besslerwheel.com/forum/viewtopic

Asa Jackson Wheel Links:

http://suncitydave.info/asawheel.htm

Here’s an ‘interesting’ one (called pinwheel) that I don’t yet understand

http://www.greenoptimistic.com/free-energy-generator-gravity/#.VPi2Zyjtj_9

Here are wheels that, in my opinion, will not work… But it’s important to know WHY they don’t work so that we can design a wheel that WILL work!

Virtual ‘museum’ of ‘unworkable’ devices. Very Educational

http://www.lhup.edu/~dsimanek/museum/physgal.htm

Chas has done a good job, but as you can see by the Wiseman’s Wheel’s math in the original Wiseman’s Wheel eBook, I’d predict that his wheel won’t work, it will balance…

Again, the Wiseman’s Wheel’s original eBook will show you that it will not work because the water is allowed to go too low on the wheel… But even if it didn’t, I’m thinking the wheel would still balance.

This is an interesting idea (needs improvement) of using compressed air to move the weights. I’d make the weights separate and move them appropriately to the ‘gravity wheel rules’.

A Gravity Wheel that supposedly worked

and the attempts at replication (good to know why something doesn’t work)

You must be logged in and have purchased one of the following products to view this content

You can login here if you are a returning customer